Page 177 - CTS - Mechanic Diesel - TP

P. 177

MECHANIC DIESEL - CITS

EXERCISE 9.5: Perform trouble shooting in starting

system

Objectives

At the end of this exercise you shall be able to

• rectify problem of “engine not cranking

• rectify problem of “engine crank too slowly to start”

• rectify problem of “starter spins but engine is not cracking”

• rectify problem of “starter not engaging or disengaging properly.

Requirements

Tools/Instruments Materials

• Trainees tool kit - 1 No. • Cotton waste - as reqd.

• Multimeter - 1 No. • Magnetic switch - as reqd.

Equipments/Machines • Petroleum jelly, brush - as reqd.

• A light motor vehicle - 1 No.

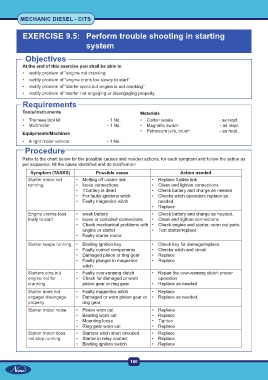

Procedure

Refer to the chart below for the possible causes and needed actions, for each symptom and follow the action as

per sequence, till the cause identified and do rectification

Symptom (TASKS) Possible cause Action needed

Starter motor not • Melting off usable link • Replace fusible link

running. • loose connections • Clean and lighten connections

• If battery is dead • Check battery and charge as needed

• For faulty ignitions witch • Checks witch operation; replace as

• Faulty magnetics witch needed.

• Replace

Engine cranks toos • weak battery • Check battery and charge as needed.

lowly to start • loose or corroded connections • Clean and tighten connections

• Check mechanical problems with • Check engine and starter; worn out parts

engine or starter • Test starter/replace

• Faulty starter motor

Starter keeps running • Binding ignition key • Check key for damage/replace

• Faulty control components • Checks witch and circuit

• Damaged pinion or ring gear • Replace

• Faulty plunger in magnetics • Replace

witch

Starters pins,but • Faulty over-running clutch • Repair the over-running clutch proper

engine not for • Check for damaged or worn operation

cranking pinion gear or ring gear • Replace as needed

Starter does not • Faulty magnetics witch • Replace

engage/ disengage • Damaged or worn pinion gear or • Replace as needed.

properly ring gear;

Starter motor noise • Pinion worn out • Replace

• Bearing worn out • Replace

• Mounting loose • Tighten

• Ring gear worn out • Replace

Starter motor does • Starters witch short circuited • Replace

not stop running • Starter in relay contact • Replace

• Binding ignition switch • Replace

160