Page 231 - CITS - ED - Mechanical

P. 231

ENGINEERING DRAWING - CITS

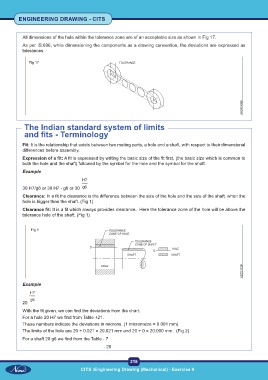

All dimensions of the hole within the tolerance zone are of an acceptable size as shown in Fig 17.

As per IS:696, while dimensioning the components as a drawing convention, the deviations are expressed as

tolerances.

Fig 17

The Indian standard system of limits

and fits - Terminology

Fit: It is the relationship that exists between two mating parts, a hole and a shaft, with respect to their dimensional

differences before assembly.

Expression of a fit: A fit is expressed by writing the basic size of the fit first, (the basic size which is common to

both the hole and the shaft) followed by the symbol for the hole and the symbol for the shaft.

Example

30 H7/g6 or 30 H7 - g6 or 30

Clearance: In a fit the clearance is the difference between the size of the hole and the size of the shaft, when the

hole is bigger than the shaft. (Fig 1)

Clearance fit: It is a fit which always provides clearance. Here the tolerance zone of the hole will be above the

tolerance hole of the shaft. (Fig 1)

Fig 1

Example

20

With the fit given, we can find the deviations from the chart.

For a hole 20 H7 we find from Table +21.

These numbers indicate the deviations in microns. (1 micrometre = 0.001 mm)

The limits of the hole are 20 + 0.021 = 20.021 mm and 20 + 0 = 20.000 mm. (Fig 2)

For a shaft 20 g6 we find from the Table - 7

- 20

218

CITS :Engineering Drawing (Mechanical) - Exercise 9